PROGRESSIVE DIE SERVICES

WHAT KIND OF STAMPING DIE WE CAN DO?

A Progressive stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die’s cutting and forming sections typically are made from special types of hardenable steel called tool steel. Dies also can contain cutting and forming sections made from carbide or various other hard, wear-resistant materials.

There are many kinds of high-speed stamping dies made by CTS Solution, all of which perform two basic operations—cutting, forming, or both. Manually or robotically loaded dies are referred to as line dies. Progressive and transfer dies are fully automated.

Progressive dies are used in higher-volume production and are designed to operate at high rates of speed. CTS Solution manufactures high-quality, reliable, and cost-effective progressive dies for the automotive, appliance, consumer electronics, and aerospace industries.

PROGRESSIVE DIE PRODUCTS LIST

|

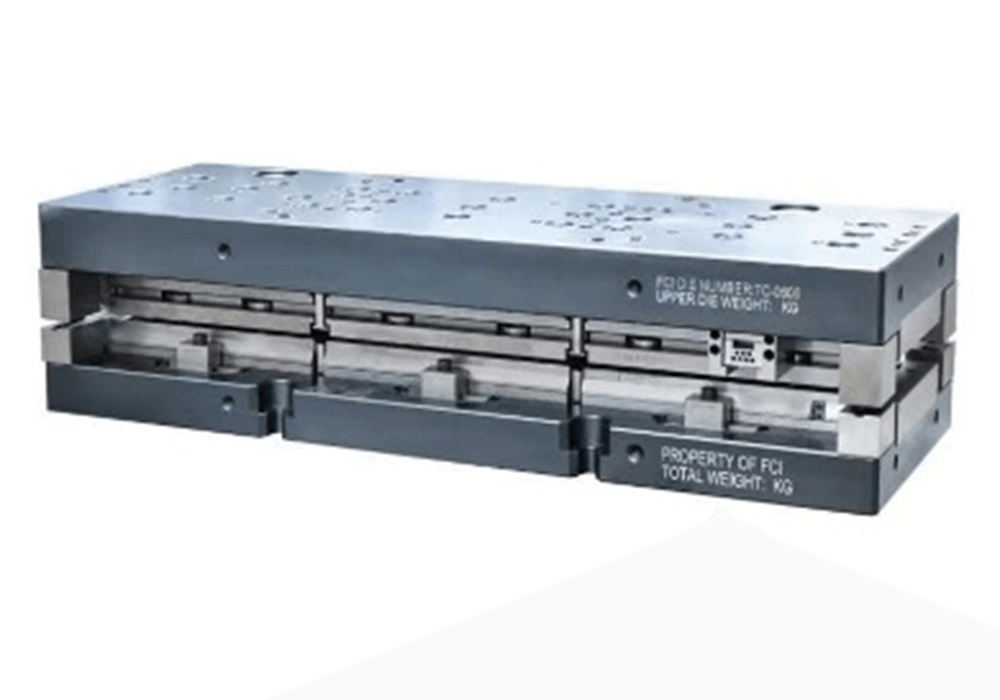

Tooling |

Modules Die |

|

|

|

|

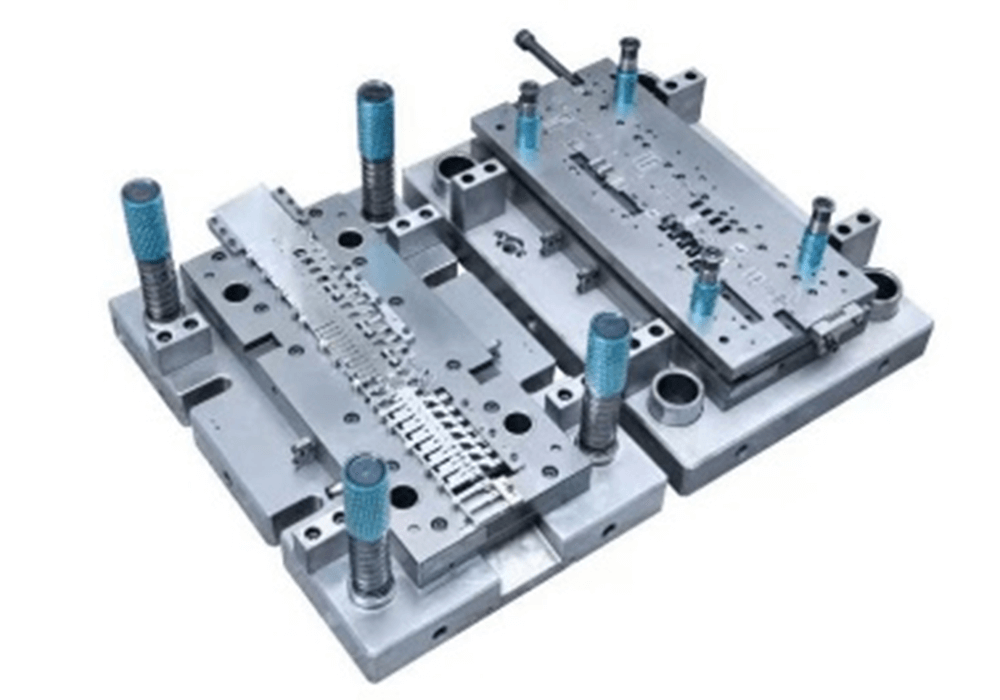

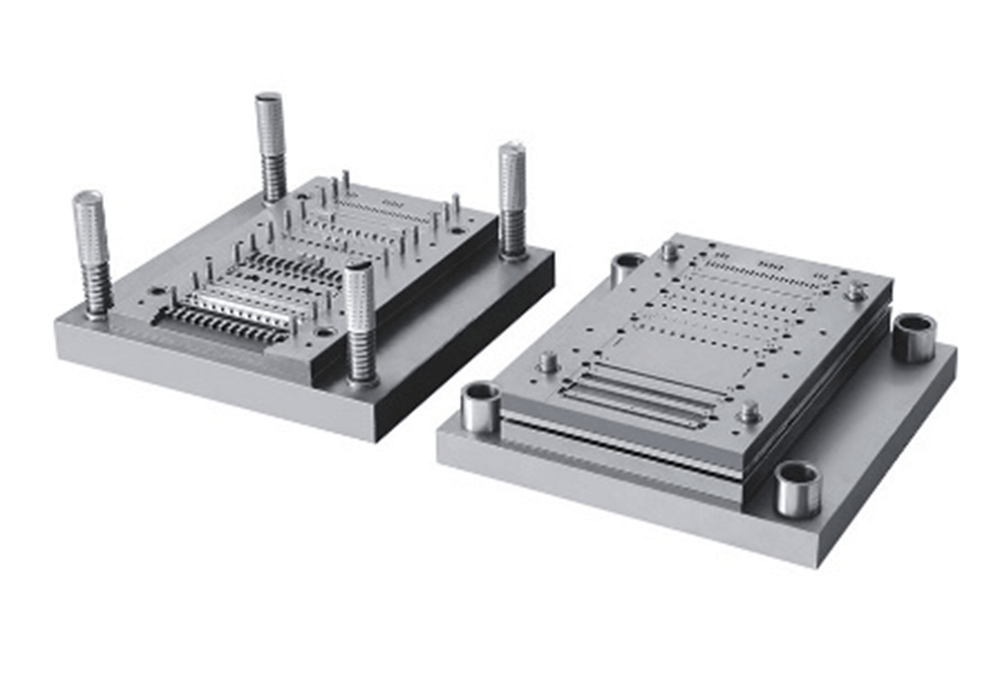

Three Plate Die |

|

|

|

|

|

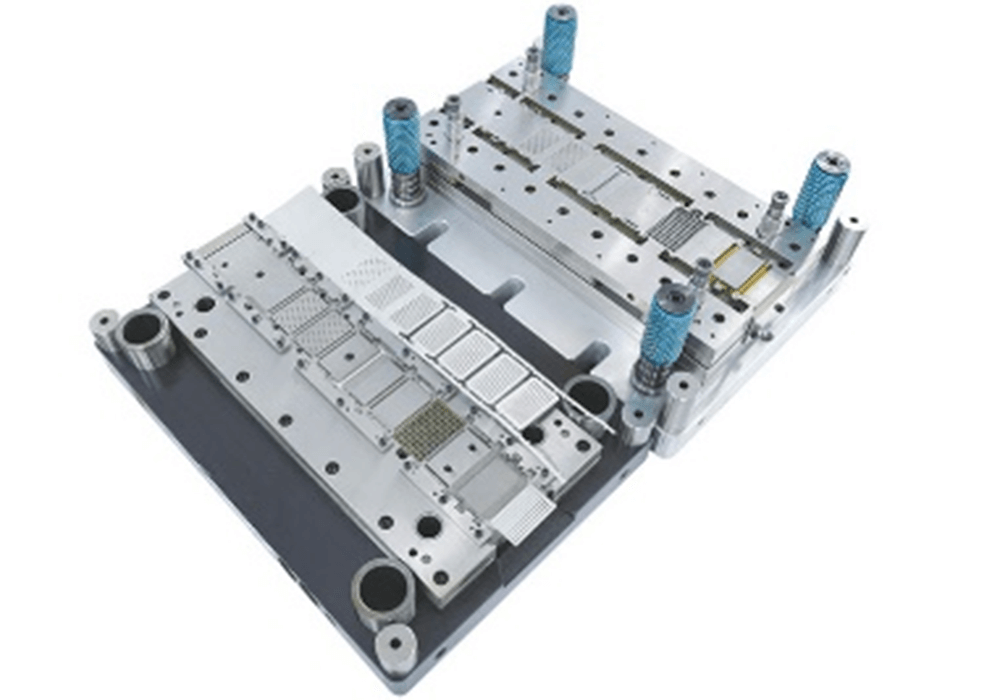

Set Dies |

|

|

|

PRODUCT PORTFOLIO. PROGESS DIE.

lStamping die development: Both 3 Plate Die and Structure.

uPrototype.

uMass production

uDesign

uFabrication

uDie assembly / Try run

uFAI&CMK Qualification. CPK under customer requirement.

lStamping die development: Both 3 Plate Die and Structure.

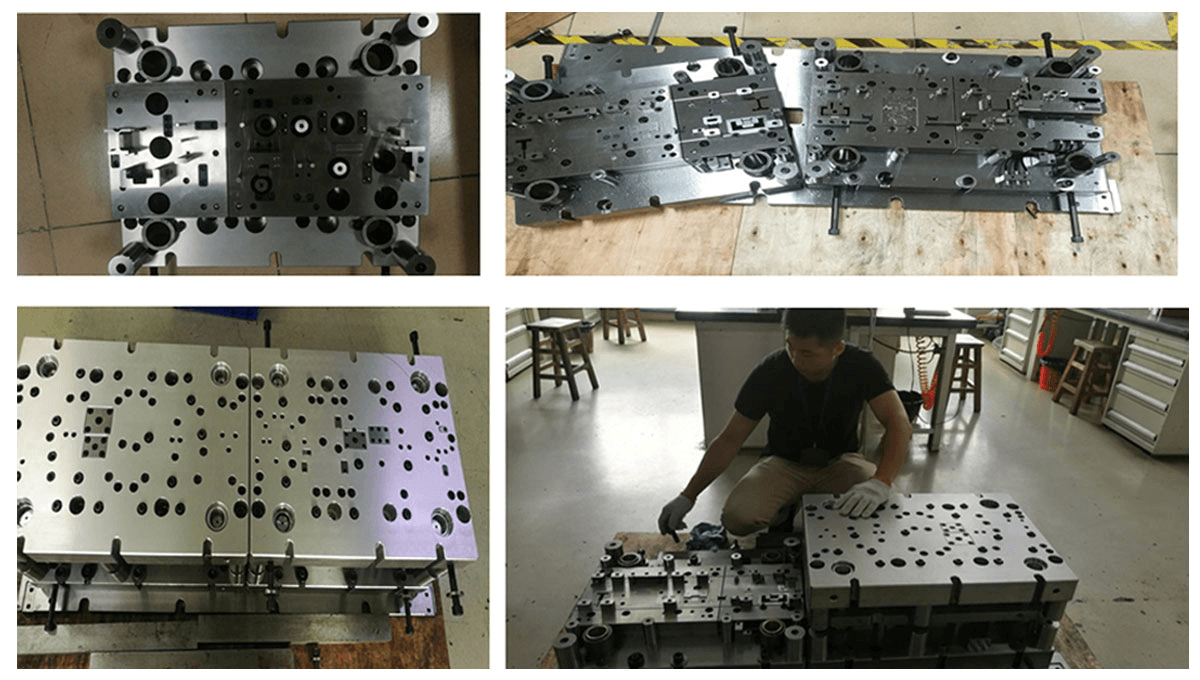

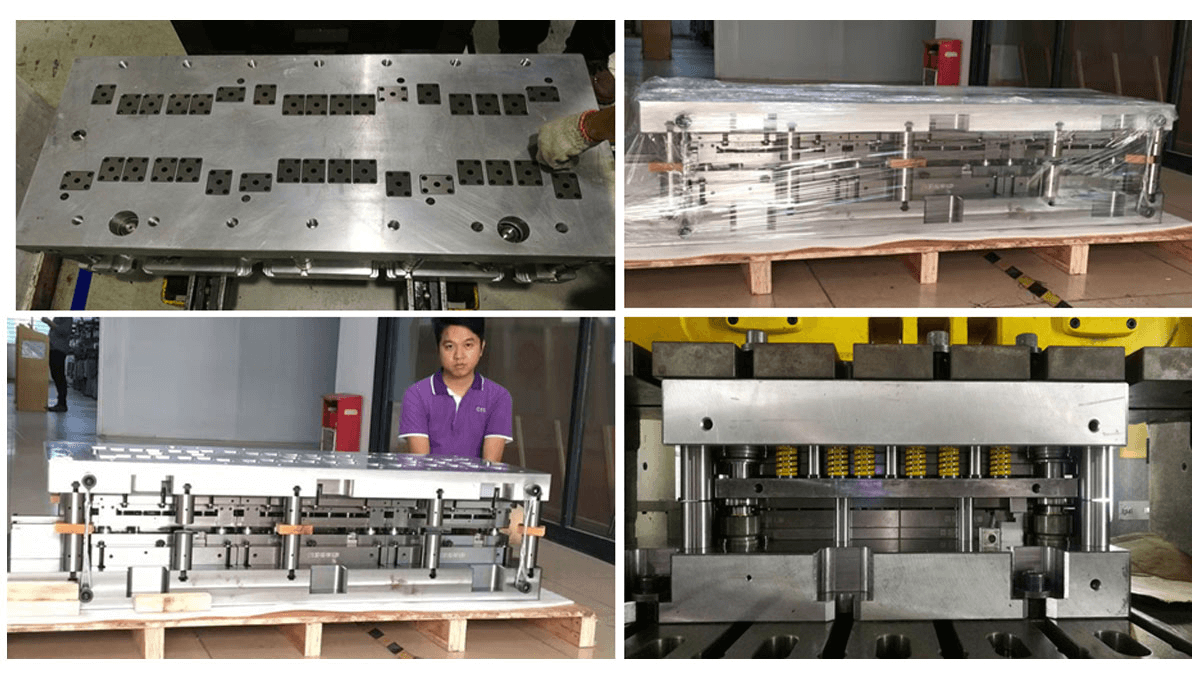

nDIE picture.

lStamping die development: Both 3 Plate Die and Structure.

nDIE Picture.

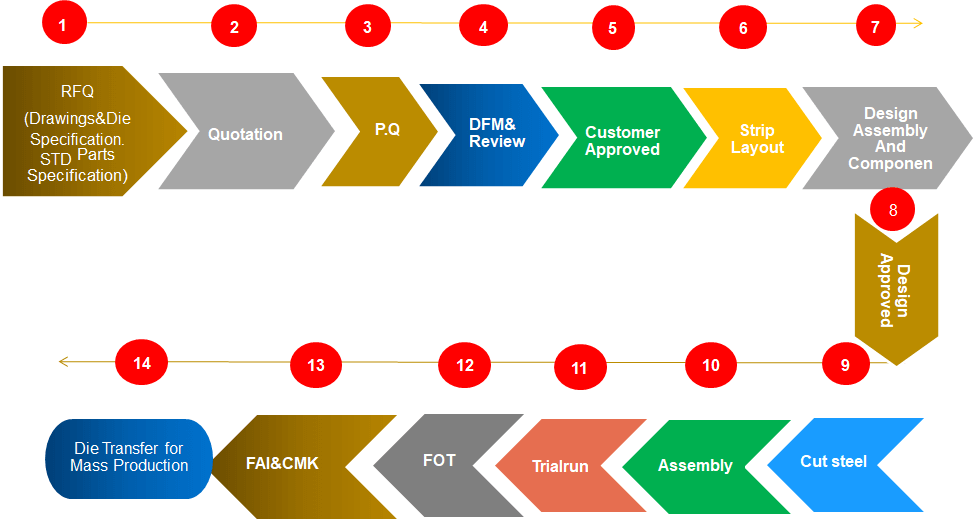

NEW PROJECT DEVELOPMENT PROCESS

HOW CAN YOU MANAGE PROJECTS-R&D TEAM WORKS?

GM of CTS Solution Steven XIAO, more than 20 Years of tooling and Stamping manufacture and project leadership experience, strong business Sense, Conduct continuous training for different level staffs, all the projects processed according to internal SOP(made & revised per customer’s demands & international conventions). Frequently design inspection & interaction with customers, all the progressive stamping dies are meet demands and easy using by customer end.

HOW CAN I CONFIRM THE PROGRESSIVE DIE IS THE ONE WE WANT?

Basically, we will provide the First sample inspection (Per R&D inspection SOP) internally, once confirmed by the in-charge project leader, we can arrange shipment then. FAI report, material certificate, and other needed files will be updated at the same time. Testing video or trial-production video can be shared for your reference.You are warmly welcomed to do site acceptance tooling testing.

HOW MUCH TIME IS NEEDED TO MAKE A PROGRESSIVE DIE?

CTS Solution can provide an initial sample within 25 calendar days. Die set design finished within 7 days, fabrication 12 days, 3 days for assembly, 3 days for testing.

WHAT CAN I GET FROM CTS SOLUTION?

When cooperated, you can get:

7*24H service from before sales to after-sales.

Easy-using & High-efficiency tooling.

On-time delivery.

The whole die set design is freely offered to you.

Spare part manufacture service.

Tooling trail & maintenance advice.

Lifetime quality tracking.

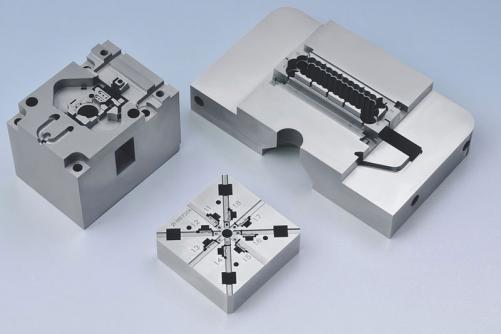

Punch And Die Set

Punch And Die Set

Punch Parts

Punch Parts